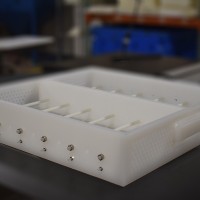

Custom Plating Basket

Custom Plating Baskets

Novo Metal Finishing Equipment provides a single-source solution for our customer’s surface finishing production needs. Designed and manufactured in the US, we create the best-in-class custom anode, dipping and dryer baskets for use in a wide range of plating processes.

The Novo Metal Finishing Equipment anode baskets are designed and manufactured in Bristol, Connecticut. Our building is situated inside of the Novo Precision campus and has been recently renovated. We are proud to be an active member of the Connecticut manufacturing sector since 2004.

With decades of experience in the metal finishing industry, we provide high quality and durable solutions that meet the needs of each specific product and system. Our equipment design team supports the entire range of product design options: from exact fit replacement baskets, to changes on existing designs, to custom-designed barrels for new systems and more. Whether you are a system integrator working on a new design or an OEM in need of a replacement basket, Novo Metal Finishing Equipment has the product solutions to meet your plating needs.

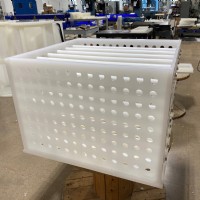

Hexagon Plating Basket

These custom mini barrels/plating baskets are the most durable dipping basket in the industry. Designed and welded just like a hexagon plating barrel, these are perfect for dipping both small parts or large. The heavy duty body allows these baskets to hold up in the harshest of environments and the perforation designs allow much better solution flow than many of its round counterparts. Handle is durable and designed with enough clearance for the largest hands and heavy duty gloves. Different door variations can be designed based off your parts to include a side clamp door, with flattened hubs to lay flat or a threaded spin top cover.

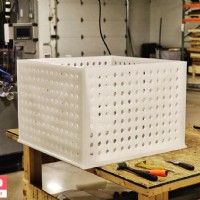

Custom Parts Tumbler

Novo manufactures custom parts tumblers built to your exact equipment specifications. Each tumbler is made to order to ensure proper fit, consistent performance, and optimal processing results within your existing finishing or tumbling systems.

Our tumblers are available in high-quality polypropylene or stainless steel, offering excellent durability and chemical resistance for demanding industrial environments. The hexagonal internal pattern promotes superior parts churn and uniform tumbling, helping improve consistency while reducing cycle times.

Every tumbler features a custom foot pattern engineered to lock securely into your equipment. Feet can be angled and positioned to maximize part movement, improve media flow, and deliver the best possible tumbling results.

All Novo parts tumblers are manufactured and assembled in the USA, ensuring high quality, dependable performance, and fast turnaround times.

Request a Quote ›The Novo MFE Advantage:

-

Increase Plating Quality

Our baskets are fabricated with your process mind. We collaborate with you to determine the ideal design qualities of your basket. Our industry knowledge translates to better fluid flow and reduced trapped material throughout the process. -

Increased Basket Life

We design our products to withstand normal mechanical and chemical stresses. We determine the perfect balance between fluid drainage and material catch points in order to minimize rinse time. Less processing time means increased basket life and reduced processing time. -

Reduced Process Costs

Novo MFE baskets are made-to-order for exact system fit. We design our products to help our customers maintain process consistency, uniform plating thickness and tank cleanliness.

Contact Us

Novo Metal Finishing offers a wide range of metal finishing services and products customized to meet your specific needs.

Contact Us ›