-

What are production plating barrels?

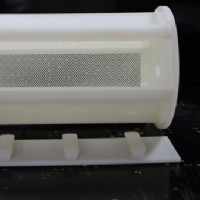

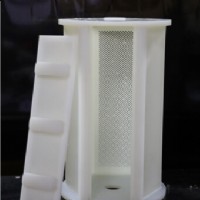

Production plating barrels are industrial-grade rotating cylinders used in the metal finishing industry to electroplate large quantities of small and bulk parts efficiently. Designed for use in production plating systems, they tumble parts during plating to ensure uniform coating coverage and improve throughput compared to traditional rack plating methods.

-

How are Novo Metal Finishing’s plating barrels different from other barrels?

Novo’s plating barrels are engineered with precision features like optimized perforations, corrosion-resistant materials (e.g., ProKnob Polypropylene), modular design, and multiple door options. These enhancements improve production plating efficiency, solution flow, and durability, while minimizing drag-out and maintenance downtime.

-

What types of production plating barrels does Novo Metal Finishing offer?

Novo Metal Finishing designs and manufactures a wide range of product plating barrels, including:

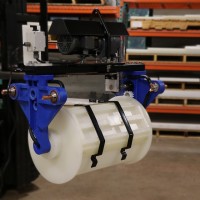

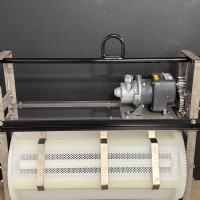

• Tank-driven or self-contained motorized production plating barrels

• Custom-size barrels to fit specific part volumes and tank sizes

• Various perforation and door styles for optimized plating performanceThese options support manual and automatic hoist systems in plating lines.

-

Can Novo Metal Finishing Customize a plating barrel for specific applications?

Yes. Novo specializes in custom plating barrels and can manufacture units of any size, diameter, perforation pattern, and door configuration to match specific production plating requirements and part geometries.

-

What materials are used in Novo’s production plating barrels?

Barrels are constructed from chemically resistant materials like advanced polypropylene to withstand harsh plating solutions and corrosion. Other options, such as steel or stainless-steel plating barrels, can be provided for heavy-load or high-temperature plating applications.

-

How do production plating barrels improve plating quality?

Novo’s product plating barrels incorporate design features that maximize solution circulation and tumbling action. This promotes even exposure of all part surfaces to the plating solution, resulting in more uniform coatings and higher overall plating quality.

-

Are Novo’s plating barrels suitable for high-volume production?

Absolutely. Production plating barrels are ideal for high-volume plating lines, enabling users to process small bulk parts in a single cycle, improving throughput, and minimizing labor relative to rack plating alternatives.

-

What maintenance is required for Novo’s plating barrels?

Novo prioritizes modular designs and easy maintenance features so that barrels and key components (like doors or gears) can be replaced quickly, reducing downtime and keeping production plating operations efficient.

-

Can Novo Metal Finishing supply replacement barrel components?

Yes. In addition to complete plating barrel units, Novo offers aftermarket parts and accessories (e.g., gears, hanger arms, baskets) to support ongoing maintenance and retrofit needs in plating systems.

-

What is the Novo MFE advantage in production plating barrels?

The Novo MFE advantage combines higher plating quality, longer plating barrel life, and lower production plating costs. Novo’s product plating barrels use single-body ProKnob Polypropylene to reduce material nesting, improve current flow, and increase plating consistency.

A seamless, extrusion-welded plating barrel design with a tight drainage pattern reduces drag-out, improves rinsing, and supports higher product plating yields with fewer process compromises.

Production Plating Barrels

Novo Metal Finishing Equipment designs and manufactures best-in-class plating barrels and plating equipment for use in a wide range of manual and automatic hoist and tank systems. We offer both tank driven and self-contained motorized units for the plating and web barrel finishing industries.

The Novo Metal Finishing Equipment plating barrels are designed and manufactured in Bristol, Connecticut. We are proud to be a part of the Connecticut manufacturing sector since 2004. We specialize in custom plating barrels and can manufacture a barrel to whatever size, diameter or style you would like. We offer plating barrels in a variety of perforations to fit both your part size as well as solution flow needs. Novo Metal Finishing Equipment also offers multiple door options to include clamp style, IO door style, slide lock and dual door center post.

With decades of experience in the metal finishing industry, we provide high quality and durable solutions that meet the needs of each specific product and system. The plating equipment design team supports the entire range of product design options: from exact fit replacement barrels for plating, changes to existing designs to custom-designed barrels for new systems. Whether you are a system integrator working on a new design or an OEM in need of a replacement plating equipment, Novo Metal Finishing Technologies has the barrel solution to meet your plating needs.

The Novo Metal Finishing plating barrel offers a range of advantages that enhance efficiency, consistency, and product quality in metal finishing operations. Designed with precision engineering, Novo barrels ensure uniform plating distribution across all parts, even on complex geometries or small components. Their advanced construction materials resist corrosion and chemical wear, extending the barrel’s lifespan and reducing maintenance downtime.

A major advantage of Novo’s plating barrels is their optimized perforation design, which promotes excellent solution flow and agitation. This results in cleaner, more even coatings with superior adhesion and appearance. The barrels are also engineered for energy efficiency, minimizing drag-out and chemical waste while maximizing throughput.

Novo Metal Finishing prioritizes modular design and easy maintenance, allowing for quick component replacement and reduced production interruptions. The use of high-quality polymers or specialized metals ensures chemical compatibility with a wide range of plating solutions—nickel, zinc, copper, or precious metals.

In addition, Novo barrels are customizable to meet specific load capacities, part sizes, and process requirements, offering unmatched flexibility for both high-volume production and precision applications. Overall, the Novo Metal Finishing plating barrel delivers consistent performance, cost savings, and long-term durability—making it a valuable asset in any modern plating operation.

Request a Quote ›The Novo MFE Advantage:

-

Increased Plating Quality

Our barrels are fabricated with ProKnob Polypropylene to reduce material catching, eliminate material nesting and increase current flow. Our single-body, thermally bent barrels are extrusion welded to the ends, creating a seamless internal volume and eliminating catch points for fluid to collect. We leverage a tight drilling pattern maximize drainage for better rinsing and faster drying. -

Increased Barrel Life

Our single-body ProKnob Polypropylene barrel is one of the most durable resigns in the industry. The extrusion welding on the ends is significantly more durable than traditional hand-welding the joints. The increased drainage facilitated by tight hole pattern and elimination of fluid catch points allows the barrel to be used for an increased number of cycles. -

Reduced Process Cost

Novo MFE barrels made-to-order for exact system fit. This eliminates any design retrofits, process compromises or extra manufacturing work-arounds. The seamless internal body reduces dragout and reduces the frequency of wastewater changeover. The textured interior reduces material catching all throughout the barrel which increases product plating yields.

Common Barrel Specification Ranges:

We have capabilities beyond the common specifications below. If you have any questions on our plating barrels or specific design needs, Contact Us.

| Material | Single-piece, thermally bent ProKnob Polypropylene body extrusion welded to Polypropylene ends |

| Plating Barrel Length (internal) | 24",30",36",42",48" |

|

Plating Barrel Width (internal, panel to opposing panel of the hexagon cross section) Chassis Options |

14",16",18" Multiple options 1,2 or 4 point pick up. Steel, Stainless structure |

| Perforation Sizes | 1/16" to 3/8" |

| Door Closures Options | Traditional Clamps, Center Lock Knob, Inside-Out (IO) |

| Electrical Contact Options | Wide variety of connection options available. |

FAQs:

Contact Us

Novo Metal Finishing offers a wide range of metal finishing services and products customized to meet your specific needs.

Contact Us ›